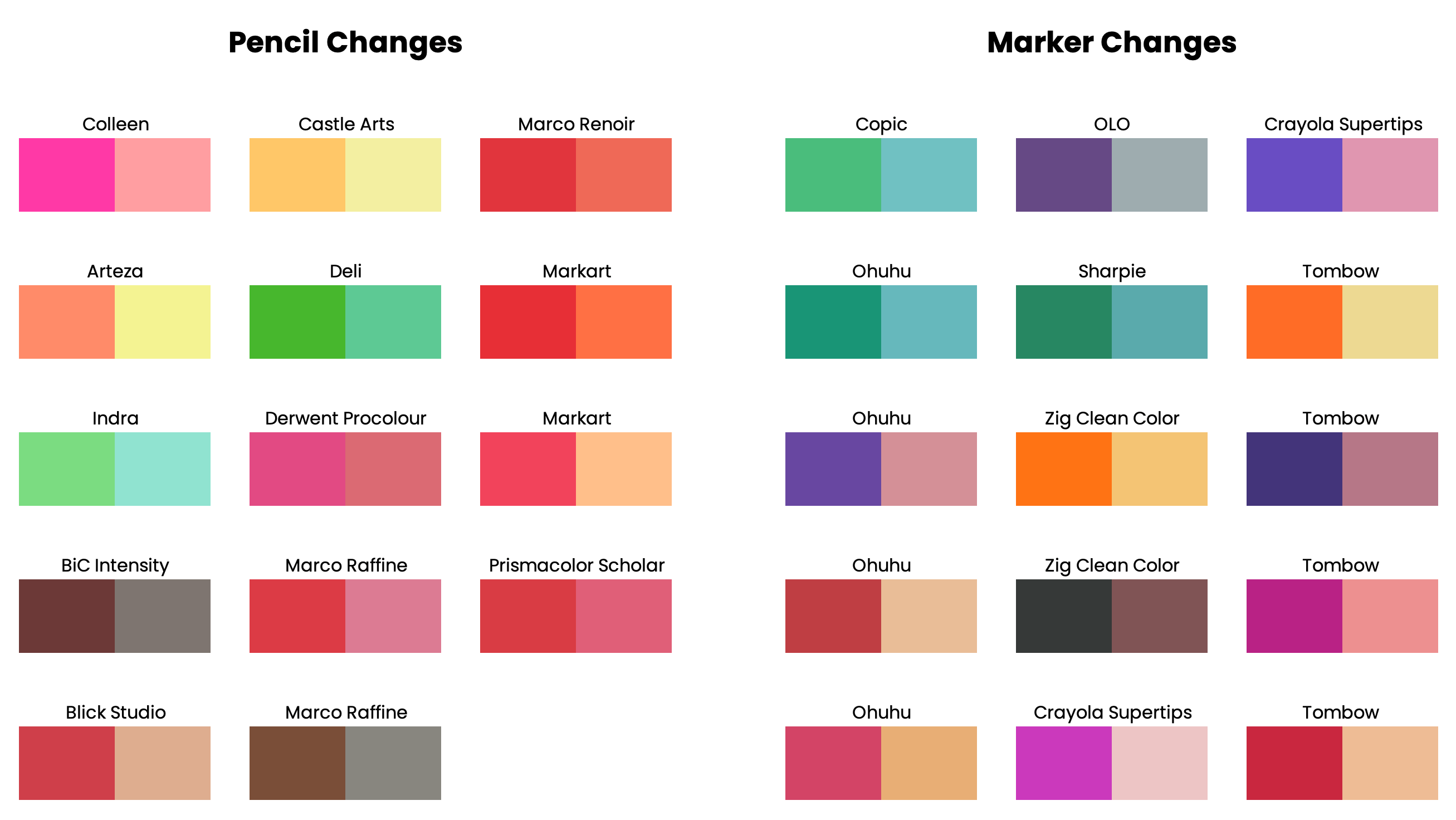

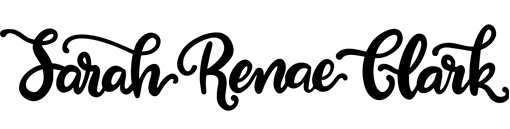

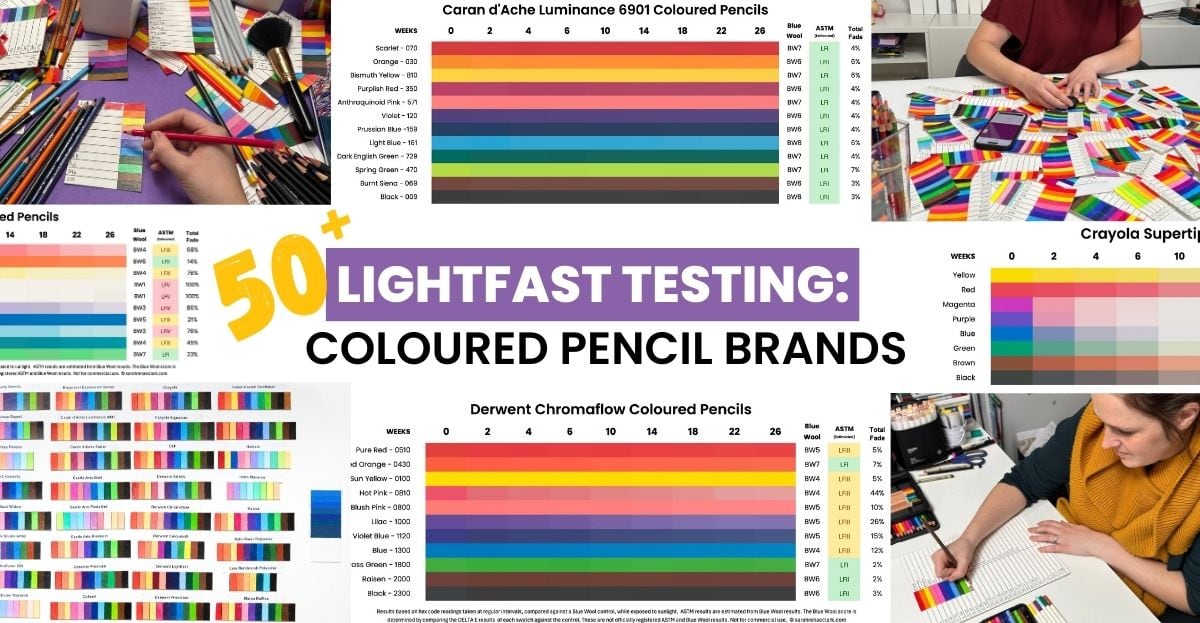

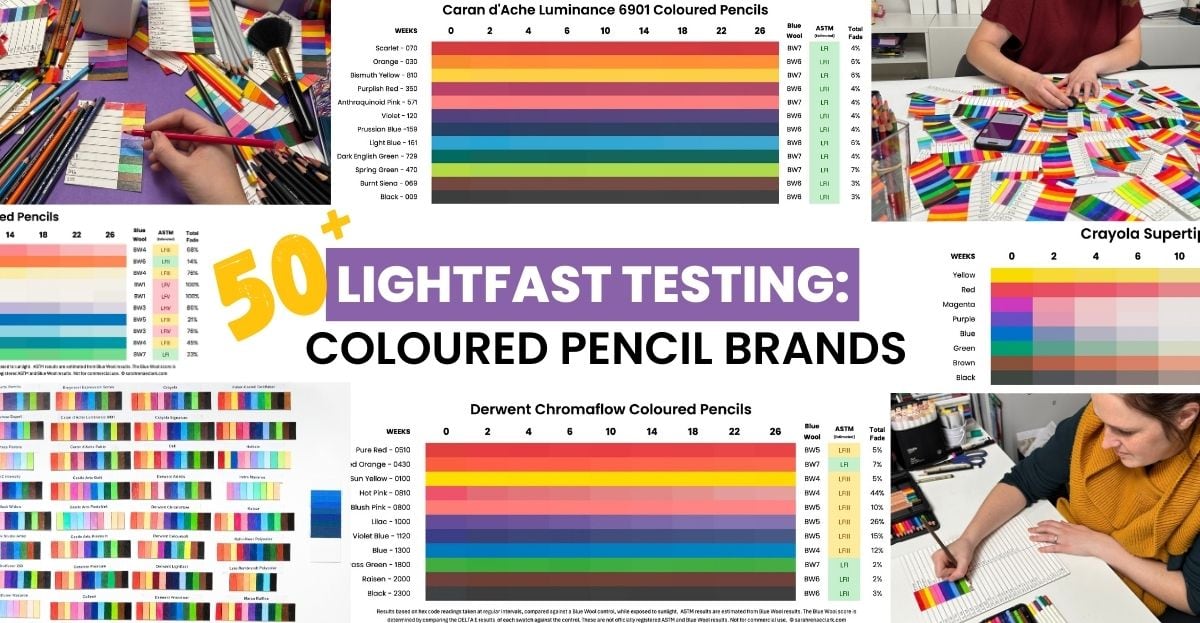

I recently tested hundreds of coloured pencils to see how they faded over time. And in the process, I found myself down a rabbit hole of learning all about how lightfast testing is done, and discovering a lot of discrepancies in the “official” testing done by companies.

You can find the full breakdown of my results in my first article, and you can see my whole journey exploring lightfastness in the video below.

But in this post, I wanted to take things a step further for the fellow colour nerds who want a closer look behind the curtain and who want to see more about my own methodology.

This article will be a LOT, I’m warning you now. But hopefully you’ll find it useful, insightful, and intriguing… and we can nerd out together!

In this article, I’ll cover:

- What is Lightfastness?

- How is Lightfastness Measured?

- How I Measured Lightfastness

- What I expected to Learn from the Lightfast Testing

- Results

- Further Reading

Before we go to the deep end, here’s a quick recap…

What is Lightfastness?

Lightfastness refers to how well a colour resists fading when exposed to light over time.

Art supplies that are “highly lightfast” are predicted to last 100 years or more in museum conditions.

Art supplies that are “fugitive” or have “poor lightfastness” can fade anywhere between 2 to 50 years, depending on their score. The worst offenders will fade within a few months of normal lighting conditions.

This fading occurs because the dyes and pigments break down when exposed to light, particularly ultraviolet (UV) rays from the sun. Different art supplies use different types of pigments or dyes and binding materials, which means some colours are naturally more resistant to fading than others.

Pigments are generally more lightfast than dyes, and coloured pencils are made of pigments – so you’d expect them to last a long time, right?

Unfortunately, this isn’t the case. And with the increase of cheaper pencil brands hitting the market, there have been a lot of claims of “good lightfastness” from coloured pencil brands who haven’t actually done any testing.

So that’s why I’m here! To test the untested. And to shed some light on how coloured pencils are supposed to be tested for lightfastness (and whether it’s sufficient!)

How is Lightfastness Measured?

When I first approached this project, I had only heard of the ASTM D6901 lightfastness test that Caran d’Ache Luminance and Derwent Lightfast coloured pencils used.

And I found it interesting to see brands like Faber-Castell claiming that they had a “more reliable” testing process – the blue wool method.

These are the 2 tests that I’ve focused on during my own process, but I’ve since learnt that there are a number of other tests that brands are claiming to use – some of which are designed for textiles or other media, and probably aren’t sufficient for coloured pencils.

Let’s break down these main testing standards below, including their process, their benefits, and their shortcomings:

- The Blue Wool Scale

- ASTM D6901

- CPSA Method

- Other Lightfast Testing Methods

One thing worth highlighting – all of these tests take time. If a test is done too quickly, the results can’t accurately determine how a pigment will perform over time. In my own experience, I think a test should run for at least 4 weeks, regardless of the methods used (some methods will need longer).

The Blue Wool Scale

The Blue Wool Scale tests lightfastness by comparing how colours fade against a standardised blue wool sample, also known as a Textile Fading Card.

It is used by Faber-Castell, Derwent, and many other coloured pencil manufacturers, and is considered to be a reliable testing method.

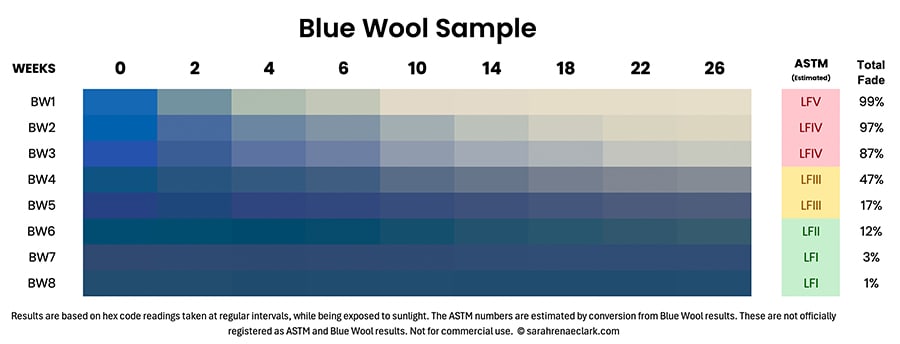

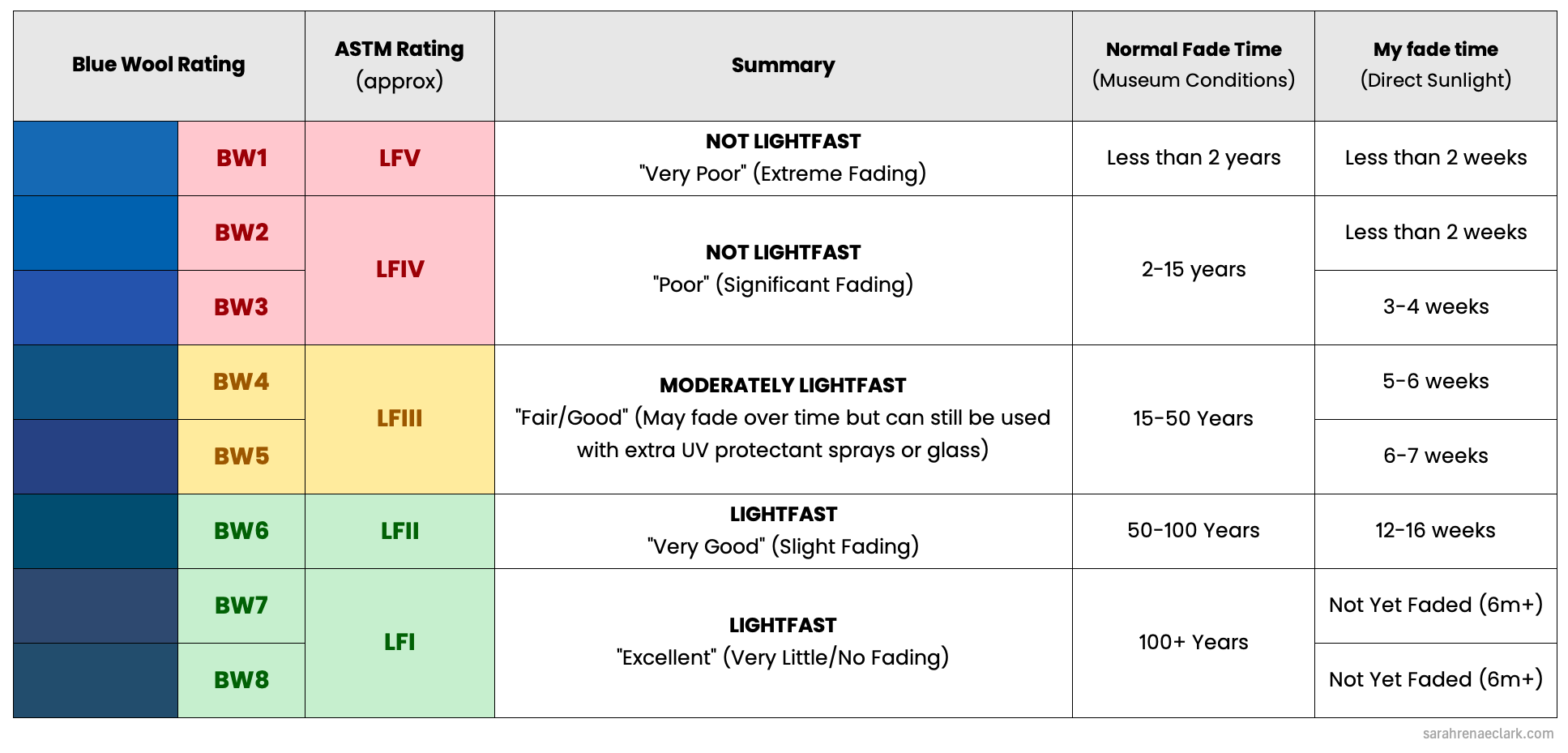

The Blue Wool Scale consists of 8 strips of wool dyed with pigments that each fade at a known rate. The first strip (Blue Wool 1) fades the fastest, and the last strip (Blue Wool 8) fades the slowest. Each level is twice as lightfast as the one before it, meaning they fade from top to bottom in a consistent order.

Under normal light, the first Blue Wool strip (BW1) will begin to show fading within 3 hours to 3 days. The final Blue Wool strip (BW8) will start to fade in 6-18 months.

Here are my own Blue Wool fading results within direct sunlight:

How is the Blue Wool Scale Testing Done?

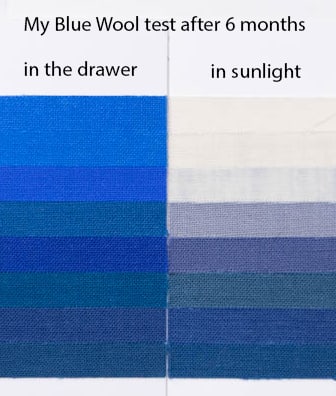

Each coloured pencil is swatched out twice, with one sample being exposed to sunlight or UV light over time, alongside the blue wool sample.

The second sample is the control and is kept in a dark place. This is used to measure the changes when compared to the swatch that has been exposed to light.

As the wool and swatches fade, the goal is to determine which strip of wool best replicates the fading patterns of each swatch.

This is done by assessing the first noticeable fade of each Blue Wool strip, and assigning its score to any swatches that are also showing first noticeable fade at the same time.

In practice, the test is run until the first Blue Wool strip shows noticeable fading. At this time, the testing is stopped and all colour swatches are assessed for changes against the control. If any swatches have faded, they will be assigned a score of BW1, because they faded at the same rate as the Blue Wool 1 strip. Any swatches that haven’t yet faded are better than BW1 and will continue to be compared against the Blue Wool strips in the test.

As the test is continued, it is stopped at each initial sign of fading for the Blue Wool numbers 2 to 7, and in the same way each colour will be assessed with the number according to when it first shows fading. Anything beyond a BW7 will be scored as BW8, being the highest score.

The Benefits the Blue Wool Scale Test

Using the Blue Wool sample is an effective way to eliminate many of the variables that make lightfast testing expensive and hard for the average person to do. Things like sunlight, humidity, and weather conditions can change how pencils fade… so a Blue Wool sample acts as a calibration method to make the results useful and measurable, regardless of the season or whether you have access to a UV light.

It’s also relatively easy to find a Blue Wool sample card online. They are usually under $50 and so it’s an affordable test that anyone can replicate.

The Downsides of the Blue Wool Scale Test

The Blue Wool method doesn’t take overall fade into consideration.

In my own testing, I noticed that some swatches faded really quickly, but then stopped fading. Others faded slowly over time, but showed more overall fade after the full 6 months of testing.

Both of these data points are important in considering how pencils perform, but the Blue Wool test only accounts for the first.

Further Thoughts on Blue Wool Scale Testing

I’ve also seen many brands and organisations use a Blue Wool sample in in their testing, but not actually use the Blue Wool results for their scoring. This isn’t a true Blue Wool Scale test, and can confuse consumers into thinking the test was more thorough than it was.

Some brands also stop their testing before the final samples have faded, which means that their results can’t be completely accurate. In practice, if the testing is stopped at Blue Wool 6, for example, it’s impossible to know which swatches can be categorised as “BW7” or “BW8” and they should instead be categorised as “Above BW6”

The lower the number, the less useful the final results are.

ASTM D6901 (American Society for Testing and Materials)

The ASTM D6901 standard is specifically designed by the American Society for Testing and Materials for testing the lightfastness of coloured pencils. This method involves exposing samples to a controlled amount of light using a xenon arc lamp, which simulates prolonged sun exposure.

At the end of a pre-determined testing time, all pencils are graded on a scale from I to V, according to how much their final color changed from the original swatch. I being the most lightfast and V being the least. Only pencils rated I or II are considered archival quality and suitable for long-term use.

Similar to the Blue Wool Scale method, each pencil is swatched twice, with one swatch being exposed to the light and the other kept in the dark as the control.

It is a highly controlled test and provides consistent results more quickly than solar or UV tests, and without variables like weather, making it repeatable across many coloured pencil brands, but also very expensive to do. In fact, the only brands who claim to have used the ASTM D6901 method are Caran d’Ache, Derwent and Prismacolor – and only the Caran d’Ache Luminance and Derwent Lightfast pencils carry the “Lightfast” stamp from the ASTM (meaning all of their pencils officially scored a I or II)

How is ASTM D6901 Lightfast Testing Done?

The ASTM method includes 2 separate tests- one under natural daylight through window glass, and another in a simulated environment using a xenon arc tester.

The xenon arc testing is done in a controlled lab, with a xenon-arc chamber that simulates UV exposure under a very specific set of conditions.

They create 10 swatches of each colour, allowing them to test multiple swatches in each of the above methods, along with some available as a control, and spares available if there are discrepancies in the results that need retesting.

The swatches are tested for a specific time period, determined by how long it takes for the total radiant exposure to reach a certain threshold. Specifically, specimens are exposed until they receive a total radiant exposure of 510 kJ/m² at 340 nm, which is equivalent to 1260 MJ/m² of full-spectrum solar radiation.

Practically, this is approximately when BW3 reaches a difference of ΔE 8.

Their total fade is measured with a spectrophotometer or colorimeter, which records an accurate digital record of each colour. For further accuracy, the ASTM takes 3 measurements of each colour and records the mean of the 3 results.

The difference between colours is calculated using ΔE (Delta E)*ab, which determines the difference between 2 colours in the L*A*B* colour space and assigns a number, with ΔE0 being no difference, ΔE2-5 being a slightly noticeable difference, and numbers above ΔE10 being obvious differences in colour.

NOTE: There are a number of different colour spaces that have been developed over the years to best measure colours in the most “perceptually accurate” way – more on this below. The ASTM uses the CIE 1976 L*A*B* colour difference equation.

The ASTM system ranks the final results based on the Delta E scores as follows:

| ΔE Score | ASTM Ranking | Description |

|---|---|---|

| 0 to < 4.0 | LVI | Excellent Lightfastness |

| > 4.0 to < 8.0 | LV II | Very Good Lightfastness |

| > 8.0 to < 16.0 | Lightfastness III | Fair Lightfastness |

| > 16.0 to < 24.0 | Lightfastness IV | Poor Lightfastness |

| > 24.0 | Lightfastness V | Very Poor |

If one of the methods of testing shows a different final ranking to another from the same colour, the test is done again with the spare swatches to either determine which test was more accurate, or to calculate the mean of all 3 results and provide a final score.

The Benefits the ASTM D6901 Lightfast Test

The highly controlled approach to this testing makes it a reliable source of information.

The Downsides of the ASTM D6901 Lightfast Test

The complexity, time and cost of this testing makes it unreachable for most companies. Because there are no regulations around lightfast testing in general, there are no major incentives for brands to go through this process.

In fact, some brands go as far as to say that the ASTM D6901 isn’t as precise as the Blue Wool method.

Further Thoughts on ASTM D6901

The ASTM have done thorough research into how their testing should be done. You can find the full paper here detailing their comparisons between various xenon arc tests compared to Florida and Arizona sunlight tests. They determined that the sunlight tests were able to distinguish the rank order of lightfastness just as well as the xenon arc tests, although the sunlight tests didn’t provide as practical results in absolute numbers or repeatability of testing.

They also suggested testing the same pigment 3 times to reduce variability in results. I think this would be a great suggestion, but it also makes lightfast testing even more time consuming and expensive.

CPSA Method (Colored Pencil Society of America)

The Coloured Pencil Society of America does its own lightfastness testing for various coloured pencils and provide the results in a workbook to their members.

They follow ASTM standard D5383, which is another standard available for lightfast testing markers, pencils, pastels, coloured inks and airbrush colours, using the Blue Wool Method.

It is a non-laboratory visual approach to testing, which stops when Blue Wool 3 reaches a change of around ΔE8. At a glance, this is similar to the ASTM D6901 exposure time.

CPSA Lightfast Colour sample.

How is the CPSA Lightfast Testing Done?

The coloured pencils are swatched on a test board, along with the Blue Wool textile fading card, then half of each sample (including the blue wool) is covered to block out sunlight and the other half is exposed.

The swatches are placed at a 45 degree angle in an outdoor box with a clear glass lid, which faces south, exposing the uncovered swatches to the sun.

When the Blue Wool 3 appears to have faded to the correct amount, the test is stopped. This is determined by someone comparing the Blue Wool 3 faded swatch against a Munsell grey card.

Then the swatches are assessed by 5 different volunteers, who allocate each colour a score from 1 to 8, based on which Blue Wool sample it best represents.

The average of the 5 scores becomes the final rating for each swatch, and it is converted to a score of either I, II or III.

The Benefits the Test

This test is a simplified version of the ASTM D6901 and is far more accessible for anyone to replicate.

The Downsides of the Test

All comparisons and measurements during this test are done by eye, so they can be subjective. Even with multiple volunteers, using a spectrophotometer would be a far more consistent method of testing the changes in colour of each swatch and determining when to stop the initial test.

Also, the results aren’t publicly available. You need to become a member and reach out to them via email to receive a copy. I haven’t been able to get a copy of the results, even after speaking with the CPSA directly.

Further Thoughts on the CPSA Testing

I would love to see CPSA update their method of lightfast testing to include more accurate measurements of the data and remove the subjectivity of doing everything by eye.

It’s also easy to mistake this for the Blue Wool Method, but the true Blue Wool method assigns scores based on when a colour first shows fading. Instead, this test compares the final fade to the most similar Blue Wool strip. Both methods have merit, but would be far more accurate if used together.

Other Lightfast Testing Methods

Many art supply brands conduct their own internal lightfastness testing and provide ratings on their packaging. While these ratings can be helpful, they are not always standardised across brands, making direct comparisons difficult.

There are currently no legal requirements regarding lightfast testing. Compliance and testing is voluntary, and there is a huge lack of transparency when companies make claims of lightfastness.

Some manufacturers use their own systems, while others follow established methods like ASTM or the Blue Wool testing we just discussed.

Here are some documented examples of other testing methods used by coloured pencil brands:

Caran d’Ache (Luminance): Officially tested according to ASTM D6901

Caran d’Ache (Pablo): Blue Wool scale scores at 150 hrs of light exposure

Faber-Castell: The Blue Wool test standard, comparable to ASTM D 5383-02 and ASTM D5383-97.

Holbein: Tested in-house according to ASTM D6901

Prismacolor: Tested according to ASTM D6901-06

Marco (Tribute): Xenon lamp radiation test for 22 hours according to the standards GB/T8427 and GB/T730 (Chinese textile lightfast test standards)

Woomer: Xenon Lamp test according to “the customer requirements” and QB/T 2586-2014 (Chinese standard for oil pastel). Blue Wool sample 5, measured by gray card grade.

It’s important to be careful about claims of pencils being “good lightfastness” or “very lightfast pencils” without comparing their results to ASTM D6901 or official Blue Wool testing. Many brands use selective results and careful wording to deceive customers into assuming that their pencils are highly lightfast, when in fact, they are the same as most other brands.

How I Measured Lightfastness

With all of this in mind, I have built my own method for lightfast testing, combining the practical takeaways from each of the industry-recognised methods, while also working within the limitations of my own resources.

Creating the Swatches

I started by carefully swatching a variety of coloured pencils and markers on archival-quality paper, ensuring that any fading would be due to the materials themselves rather than paper degradation. For each brand, I selected up to 12 colours, providing a broad range of pigments to compare. I labelled each swatch from the start, allowing me to track its progress throughout the experiment and compare results accurately.

I also wiped each swatch down with a tissue to remove any surface wax bloom before the testing began (this was also noted in the ASTM D6901 testing).

Sunlight Exposure vs. Control

To measure fading accurately, I created three identical swatches for each colour:

- Sunlight Test – One set was placed in direct sunlight for six months to observe how prolonged light exposure affects the different pigments.

- Control Swatch – A second set was stored in a dark drawer to serve as a reference point.

- Fresh Comparison Swatch – A third set was created at the end of the test period to compare against both the sun-exposed and control swatches. This helped confirm whether the control swatches had also experienced any fading.

Using the Blue Wool Method

To make sure my results were as accurate as possible, I tested all my swatches alongside the same Blue Wool textile fading cards that I mentioned earlier.

By comparing my results directly against these strips, I was able to “calibrate” my fading results and align them with industry-standard categories, despite not being in a controlled environment.

My Colour Measurements

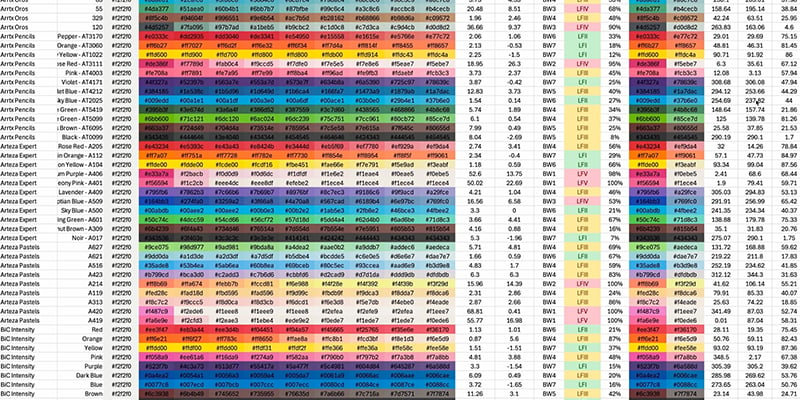

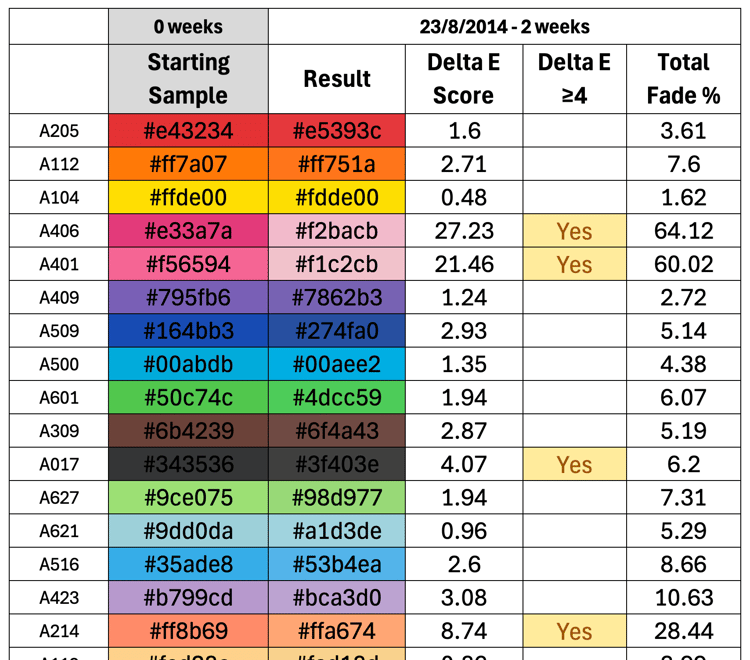

Rather than relying on visual inspection alone, I measured each swatch’s colour every few weeks using a personal spectrophotometer: the Nix Mini Colour Scanner. This device scans colours in the real world and converts them into digital colour values (hex codes), making it easier to track subtle changes that might not be obvious to the naked eye.

I recorded the colours of each swatch at 0, 2, 4, 6, 10, 14, 18, 22 and 26 weeks. I originally also recorded 30 weeks, but this data showed some obvious errors so I decided to exclude it from my final analysis.

I gathered all of my findings in a database, removed any obvious errors or outliers in the data, and used the results to measure the scores of each pencil, using the Blue Wool Method and converting it to an approximate LV score.

Measuring the Colour Changes with L*A*B*

To accurately measure how much each colour faded, I first converted all my colours into the L*A*B* colour space. This is a system that represents every colour in a 3D space based on how humans perceive them.

I was able to use a Python code to convert all of my data from hex codes to their LAB equivalents.

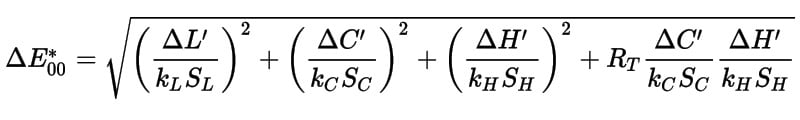

I used a colour distance formula known as CIEDE2000 to measure the distance between the colours.

The ASTM D6901 uses the CIELAB colour difference formula, also known as CIE76. This formula is now outdated, because it turned out to not be as perceptually accurate as intended, especially in highly saturated colours. It was superceded in 2001 with the CIEDE2000 formula.

This updated formula is one of the most precise methods for comparing colour differences as seen by the human eye.

The distance between 2 colours is measured as ΔE (Delta E)

- If ΔE = 0, the colours are exactly the same.

- A small number (like 1 or 2) means the difference is very hard to see.

- Bigger numbers (like 5 or 10) mean the difference is obvious.

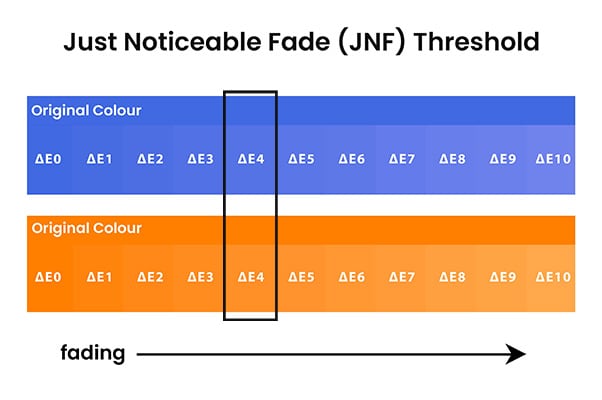

Measuring First noticeable Fade

When it comes to assigning each colour with a score on the Blue Wool scale, I’m not just looking at how much they’ve faded after 6 months. Instead, I used the colour difference calculations to identify when each colour started to show noticeable fading, compared to the blue wool reference.

Humans can usually see even very small changes in colour, but the recognised method is known as a JNF (Just Noticeable Fade) Threshold.

This is reached when ΔE is greater than 4.

Color Change Considerations

One aspect of testing that doesn’t seem to have been specifically mentioned in any other testing is the change in hue of some of the swatches. Some of the colours changed from green to blue, for example.

This further highlights the importance of using CIELAB measurements, and not solely relying on matching colours to a grey scale card.

Even with the huge shift in colour, some of these colours haven’t reduced in their lightness or saturation – and all 3 need to be considered for practical use. The CIE2000 calculation is a great way to consider all aspects, instead of just “fading” to a lighter colour.

Blue Wool Lightfastness Ratings

When it comes to assigning each colour with a score on the Blue Wool scale, I’m specifically assigning them based on when each colour started to show noticeable fading (reaching the JNF threshold), compared to the blue wool reference.

So if a colour swatch reached the JNF threshold at the same time as Blue Wool 3, it received a score of BW3.

And because so many colours started fading within the first 2 weeks without more detailed measurements, I also calculated initial fade rates for the first 3 results, and acceleration of each colour for the next 3 results (did the fading speed up or slow down compared to the initial rate?) to help better separate the colours that faded similarly to the Blue Wool 1, 2 and 3 samples (These all showed some level of fading by the 2 week check)

If I were to do this test again, I would be more intentional about watching the Blue Wool swatches and measuring the colours at each exact JNF threshold point.

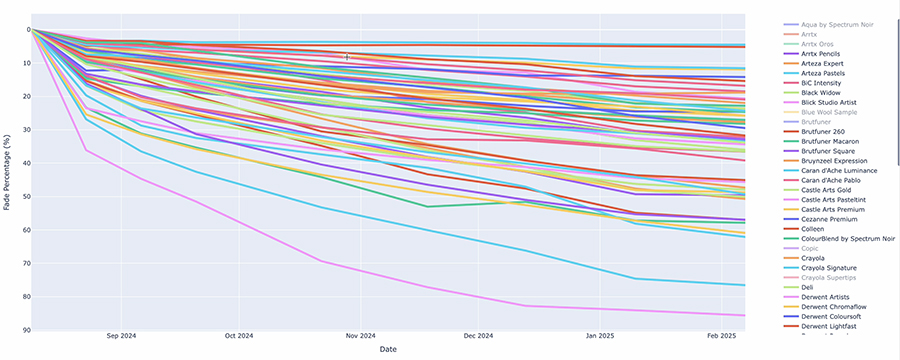

Measuring the Total Fade over 6 Months

I also converted these results into fade percentages across the 6 months to make things a little easier to follow.

I did this by taking a sample measurement of the paper without any colour, and the final wool sample of BW1, long after the colour had faded. I compared this to the original swatch of each colour, creating a graph for each colour where 0% fade was the full colour, and 100% fade was the paper/wool underneath.

A 0% fade meant no change, while 100% meant the colour was completely gone.

I did this at the 6-month mark, so it isn’t calibrated to any particular industry method.

ASTM Lightfastness Ratings

The ASTM scoring system is a little different, but it can be roughly estimated by translating the Blue Wool scores, which is what I’ve done with my results. While not official, it gives a clearer picture of how each material might perform over time compared to other brands.

After further research, I realise that I might already have all I need to calculate a more accurate ASTM score, by identifying when my own Blue Wool 3 reached ΔE8 and calculating the total fade rate at this point in time for each swatch.

This is something I might explore, but for now I’ve published the approximate ASTM scores, based on a conversion from Blue Wool. The total fade is also available as an interesting reference for comparison.

In fact, I think the combination of these methods is far more accurate in showing how a pencil performs when compared to using only one of these tests. The bigger picture of the data with multiple measurements allows us to see patterns in which pencils faded quickly and which faded more slowly, but for a longer time.

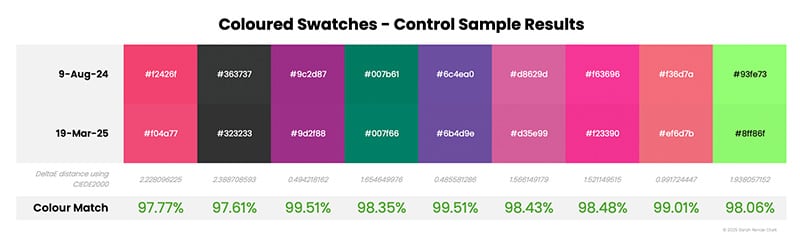

The Control

As a final test, I also wanted to make sure my control swatches were still reliable for comparison, even though I had electronically collected the data at each stage.

I re-applied new pencil swatches next to the original control and took a measurement of a small sample of the worst performing pencils.

These results showed hardly any change, not even reaching the JNF threshold.

This wasn’t surprising, since my control was protected from light during the entire 6 months. But it was still worth checking, and I’ll be curious to check back on the control again in the future to see if there have been any noticeable changes in colour.

What I Expected to Learn from the Lightfast Testing

Going into this project, I wasn’t just curious about which brands would fade – I wanted to see how they faded. Would some colours disappear quickly while others held strong for months? Would the results vary across brands, and would price make a noticeable difference?

When I started exploring this 6 months ago, I had no idea about how lightfast testing worked or what was considered a reliable source of information. And with all of the conflicting “lightfast results” provided by brands, I wanted to find answers for myself and for the broader community – both to help in purchasing decisions, but also to better understand the important of lightfastness and when to (or when not to) consider further UV protection for your work.

I expected to find some interesting changes in the pencils, but I never expected to unravel a web of deceptive claims made by manufacturers about their products’ lightfast ratings.

I thought my testing was hardly scientific. But after understanding more about the industry expectations, I realise I have been able to gather an overwhelming amount of new information for a much needed discussion. I hope this can help other artists to take this testing further again, and to give us all more transparency with the marketing tactics and advertised claims from coloured pencil brands.

I’d love to see brands provide more information about their testing, and Currently, the ASTM, ISO and CPSA all have their documentation available for a fee. I think it would go a long way for many of the standards to be made available to the public so people can vet the results for themselves, but I understand that organisations like the CPSA are volunteer-based so I’m unsure if this is something they would ever consider.

For now, it’s up to you as a consumer to seek out the information for yourself – and maybe even try your own in-home lightfast test!

Further Reading

If you’d like to take a journey down this rabbit hole for yourself, here are some of the resources I used in my own research.

General Information:

- Delta E: A Key to Understanding Lightfastness Readings

- Lightfastness Tests (including history, how to test at home, and more)

- Colour Difference Formulas: CIELAB and CIEDE2000

The Coloured Pencil Society of America

Testing Standards

- Blue Wool Standards

- ISO 105: Blue Wool for Textiles

- ISO 105-A02:1993: Grey scale measurements

- ASTM D6901 Standard Specification for Artists’ Colored Pencils

- ASTM Practice for Visual Determination of the Lightfastness of Art Materials by Artists and Art Technologists

- Atlas Standards Guide 106 (Xenon-Arc Testing Standards)

Lightfast Information Provided by Brands

Leave A Comment